- Relicom

- \ Catalogue

- \ Composite materials

- \ DSC ENG CORP., Korea

- \ Aluminum flux panel "ALCOFLUX"

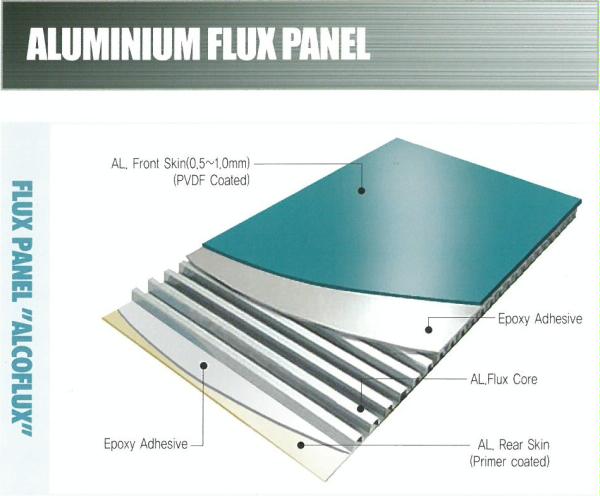

FIRE RETARDENT FLUX CORE COMPOSITE PANEL

As a composite panel which continuously jointed aluminum or tin alloyed steel core formed fabricated as the shape of flux between aluminum or galvanized steel, coated with PVDF resin or stone pattern printed skins. ALCOFLUX panel must be a solution for the problem (flatness and strength) of single metal panel of ext. & int. panel and the Is' fire-proof composite panel overcome the weak point (fire-retardant) of existing Aluminum composite panel.

FEATURES

Economical Efficiencies

Excellent Flatness

Non-Combustibility

Beautiful Outlook

Lightweight

Insulation

MAIN APPLICATIONS

Exterior, Interior panel for New Building and Remodeling

Commercial Building, Apartment,

Factory. Grand Market, Parking Tower

Building for required Insulation & Sound Absorption Effects

Office and Interior Partition

Subway Station & Column Cover

Tunnel Inner Wall Cladding

Exhibition Hall Display

| Item Classification | 4mm Flux Panel (0.6+2.9+0.4) |

|---|---|

| Thickness, mm | 4.0±0.1 |

| Weight, kg/m2 | 3.5 ±0.2 |

| Flatwise Tensile Adhesive Strength, kg/cm2 | Over 20 |

| Weatherablity,% | Over 80 |

| T-PEEL Strength, kg/25mm | 5 |

| Compressive Strength, kg/cm2 | 30 |

| Bending Strength, kg/50mm | L:25 |

| Heat Conductivity, kcal/mh °C, 20°C | W:50 0.33 |

| Combustibility | Fire Retardant (Class1) |

Standard Panel Size

1020mm x 2440mm 1020mm x 4000mm

1250mm x 2440mm 1250mm x 4000mm

Standard Panel Thickness

0.6+3+0.4 = 4mm (±0.1)

0.8+4.8+0.4 = 6mm (±0.1)